A tiny loom designed to give a miniature masterclass on Yorkshire’s textile prowess has been carefully conserved in the shadow of its super-sized sibling in Armley.

The scale model, less than half a metre high, is housed at Leeds Industrial Museum and recreates in astonishing detail the hulking machines manufactured by Barnsley’s Wilson and Longbottom, who made looms for factories around the world during the golden age of Yorkshire textile production.

Made in 1945, the miniature was once a fully working machine, and comes complete with tiny versions of the tools and accessories used in the full-sized version as well as a hand-written instruction manual penned by its original maker.

Used for demonstrations, the machine even has a half-finished green handkerchief inside along with tiny replicas of the larger punched cards which, in a full-sized loom, would determine the sequence in which threads would rise and fall during production.

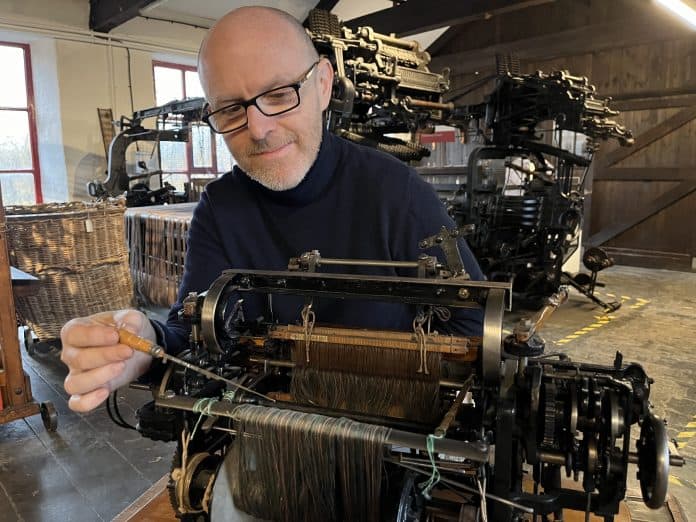

The model’s delicate cleaning took place close to the museum’s full-size Hattersley standard loom. The larger loom was made in 1933, manufactured by George Hattersley and Sons Ltd. of Keighley. The firm had a track record of making every type of loom until their closure in 1981, and each loom produced at the Hattersley works was painstakingly packed in specific order to ensure that all the parts worked properly.

Noted for their efficiency and robustness, many Hattersley looms survive today in working order, with the museum’s model even recently being used to create a specially-designed ‘Armley Weave’ cloth on site.

John McGoldrick, Leeds Museums and Galleries’ curator of industrial history, said: “Seeing both contrasting machines side-by-side really brings home the ingenuity and pride behind these remarkable looms, which dominated the Yorkshire textile industry for generations.

“Conserving the model loom, it’s clear that the maker wanted to capture the complexity of the mechanism and show exactly why these locally produced machines had become so popular and well-regarded in mills and factories around the world.

“Looking at the full-sized loom also gives a real sense of the size and power of the real thing, and it’s easy to imagine textile mills filled with these impressive machines which helped establish the county as such an important hub for the whole industry.”

Once itself the world’s largest woollen mill, Leeds Industrial Museum was built in at least the 1600s. The site was bought in the late 1700s by Colonel Thomas Lloyd, a Leeds cloth merchant, who expanded operations dramatically, so much so that Armley was soon the world’s biggest mill of its kind.

Although production ended in 1969, the site reopened as Leeds Industrial Museum in 1982 and today displays vintage machinery including traditional looms and other textile equipment.

Sponsored content